A double conversion UPS converts the incoming alternating current (AC) to a direct current (DC), so it can power the system’s battery, and then inverts the DC back to AC for powering equipment – hence the name “double conversion.”

We need to know how a UPS’s components work together so we

can better understand the UPS system and ensure that the critical load remains

online.

As shown in the Fig.1, an online double Conversion UPS has (4)

major components:

- Rectifier,

- Inverter,

- Energy Storage (Battery),

- Static Switch.

Fig.1 Components

of Online Double Conversion UPS

|

1- Rectifier |

|

The

rectifier acts as a load to the electrical mains. The primary objective of

the rectifier is to: A- Convert the incoming power supply (AC) to DC This

DC voltage is used to support what is commonly called a DC Bus, which is the

connection between the rectifier, the stored energy device, and the inverter. B-

Charge the battery All

UPS systems need a battery charger—a type of rectifier—to keep batteries

charged and recharge them after a power outage. Some rectifier systems use

what is called a walk-in circuit. This circuit ‘walks’ up its output, or the

DC Bus, slowly. Walking the DC Bus up gradually accomplishes several useful

things, including protecting the DC filter caps and reducing inrush current

to the system. Some

models of UPS systems will use a separate battery charger that can be turned

off when the batteries are fully charged. It will then monitor the batteries

and when they need to be charged it w ill turn back on. For a

double-conversion system with separate battery chargers, there needs to be a

rectifier to support the DC Bus during normal operation. C- It

also has a hidden objective which is to draw a sinusoidal current from the

mains and also to ensure the current drawn is in phase with the voltage

waveform so that the current harmonic distortion injected on the mains is

less and the power factor is better. Therefore,

Other names used for rectifiers are battery charger and AC to DC converter. The

rectifier in a three phase UPS is designed to operate under:

Taking

into consideration voltage fluctuations, the rectifier is typically designed

to operate with:

In general, the best rectifier topology should have:

This

will ensure good compatibility with Generators and also reduce the need to

oversize the DG set, incoming transformer and cable sizing for supporting the

UPS. The

technology of the UPS has evolved and different technologies are being used

in the rectifier of the UPS. A short comparison of different rectifier

technologies is given in Fig-2. Fig-2 Comparison of Different Rectifier

Technologies |

|

2- Inverter |

|

The

primary objective of the inverter is to convert DC power to AC power and to

support the loads. The DC

power can be either from the rectifier or from the battery connected to the

DC bus of the UPS System. The

inverter is a critical component as this acts as a source to the critical

loads connected to it. As a source, the inverter has to support the loads

with sinusoidal voltage waveform under below conditions:

There

are two main Inverter topologies namely with:

We already explained these topologies in article “Classification and Types of UPS – Part Seven” Inverter typologies As already seen for the rectifiers, also the

inverters can be separated in different typologies, according to the

constructive solution chosen (TYPE 1, TYPE 2 & TYPE 3) TYPE 1 It’s the single-phase inverter, with the following

manufacturing features:

TYPE 2 It’s the three-phase inverter, with the following manufacturing features:

TYPE 3

|

|

3- Energy Storage |

|

When

electrical service is disrupted (i.e., mains failure), the UPS continues to

support the load connected to it through its energy storage system. A stored

energy source provides DC power to the inverter when the normal AC power is

not available. This normal AC source could be utility or generator power. The

UPS may provide power for durations ranging from 10 to 20 seconds to several

hours. Shorter duration UPSs are designed to carry the load during the

start-up of back-up electrical generators, typically diesel engine driven

generators, and to enable a smooth transition to the generator as the power

source. In

many cases, the UPS is designed to provide power for 5 to 30 minutes. The

purpose is to enable an orderly shutdown of operations thereby avoiding an

abrupt shutdown, which would otherwise cause equipment damage, product/work

losses or a security/safety hazard. The under-desk UPS for PCs is an example.

UPS

with enough energy to provide power for several hours are somewhat rare. A

key reason is that, in most situations, it is less expensive to store energy

in the form of diesel fuel (for generators) if backup power is needed for

several hours. There are different technologies of energy storage solution available in the market like:

The selection of right energy storage system depends on:

|

|

3.1 Energy Storage system - battery |

|

Battery

is the most critical component in the UPS and is also considered as heart of

the UPS System. Without, battery the UPS is just a power conditioner. The

purpose of the battery is to provide the energy necessary to supply the load

when the mains supply in not available. Cost

of battery is a major component on the final price of the UPS solution

proposed to the customer. A

battery is an electrochemical device that stores energy at one time for use

at another. The battery uses electrical energy to store energy in chemical

form which is converted to electrical energy during the discharge of the

battery (see Fig.3) Fig.3 battery is an electrochemical device The

UPS battery may furnish power to the inverter for a few seconds, many

minutes, or hours. The battery capacity is determined by the amount and

duration of power the inverter has to deliver to the load from the battery. |

|

Types of Battery Three common

varieties of battery chemistries popularly used in UPS applications (Fig.4)

are:

Fig.4 Types of Battery |

|

3.1.1 Lead Acid Battery It is

very commonly used as the storage battery or secondary battery where

electrical energy can be stored as chemical energy and this chemical energy

is then converted to electrical energy as and when required.

Whereas

conversion of chemical energy into electrical energy for supplying the

external load is known as discharging of secondary battery. During

charging of battery, current is passed through it which causes some chemical

changes inside the battery. This chemical changes absorb energy during their

formation. When

the battery is connected to the load, the chemical changes take place in

reverse direction, during which the absorbed energy is released as electrical

energy and supplied to the load. The

principle working of lead acid battery The main active materials required to construct a lead acid battery are:

The

positive plate is made of lead peroxide. This is dark brown, hard and brittle

substance. The

negative plate is made of pure lead in soft sponge conditions. Dilute

sulfuric acid used for lead acid battery has ratio of water to acid = 3:1. During

discharging:

During

charging:

|

||||||

|

The

lead acid battery is further classified as:

|

|

3.1.1.A SMF (Sealed Maintenance Free) battery It is a battery that doesn't require topping up due to negligible water loss. It is designed in such a way that it cannot be opened or refilled. These batteries are safe, maintenance free and are suitable for most UPS applications. The SMF battery will have an additional safety valve which release the excessive formation of hydrogen, as a result of overcharging, in to the atmosphere. SMF

battery works on a recombination technology where the hydrogen gas evolved

during the charging process, is converted to water with the help of oxygen

present inside the battery container. The typical cyclic performance of the battery is less and is limited by the operating temperature and the charging profile. The

SMF battery delivers higher power at higher temperatures but the life of

battery comes down significantly The SMF battery needs to be installed in a

controlled environment to maintain the temperature at 25-27 deg C and an

additional hydrogen sensor in the battery room is recommended for

installation. |

|

3.1.1.B Tubular/Flooded Battery Tubular Batteries have openings at top to add distilled water for maintenance and safe running. These batteries are very rugged and used in Cyclic application. These batteries last longer due to robust design and are suitable for harsh environment applications. The tubular battery can be installed in any environment (other than closed air conditioner room) with proper ventilation and air exchanges as hydrogen evolution from the battery is higher when compared with SMF buttery. |

|

3.1.1.C Tubular Gel VRLA Tubular

Gel batteries require no topping of water and is a sealed, valve regulated

lead-acid deep cycle battery that uses a gel electrolyte. These type of batteries are rugged and suitable for cyclic applications but are maintenance free compared to flooded tubular batteries. |

|

3.1.2 Nickel cadmium cell (Ni-Cd) The active components of a rechargeable Ni-Cd battery in the charged state consist of:

Due to their low internal resistance and the very good current conducting properties, Ni-Cd cells can supply extremely high currents and can be recharged rapidly. These

cells can operate over a large temperature range, from +60°C down to -20°C. The selection of the separator (nylon or polypropylene) and the electrolyte (KOH, LiOH, NaOH) is also of great importance. These elements influence the voltage conditions in the case of a high current discharge, the service life and the overcharging capability of the cell. In the case of misuse, a very high-pressure may arise quickly. For this reason, these cells are equipped with a reversible safety valve, which can act several times. NiCad

cells offer a long service life (depending on the type of application and

charging unit up to 2000 cycles).

|

||||||

|

3.1.3 Lithium Ion battery Lithium-ion batteries offer several advantages over traditional valve-regulated, lead acid batteries as follows:

Therefore,

lithium-ion batteries become an appealing energy storage technology option

for energy storage. Similar to the lead- and nickel-based architecture, lithium-ion uses a cathode (positive electrode), an anode (negative electrode) and electrolyte as conductor, it consist of:

During

discharge:

During

Charging:

When the cell charges and discharges, ions shuttle between cathode (positive electrode) and anode (negative electrode). On discharge, the anode undergoes oxidation, or loss of electrons, and the cathode sees a reduction, or a gain of electrons. Charge reverses the movement. All

materials in a battery possess a theoretical specific energy, and the key to

high capacity and superior power delivery lies primarily in the cathode. For

the last 10 years or so, the cathode has characterized the Li-ion battery. Common cathode material include:

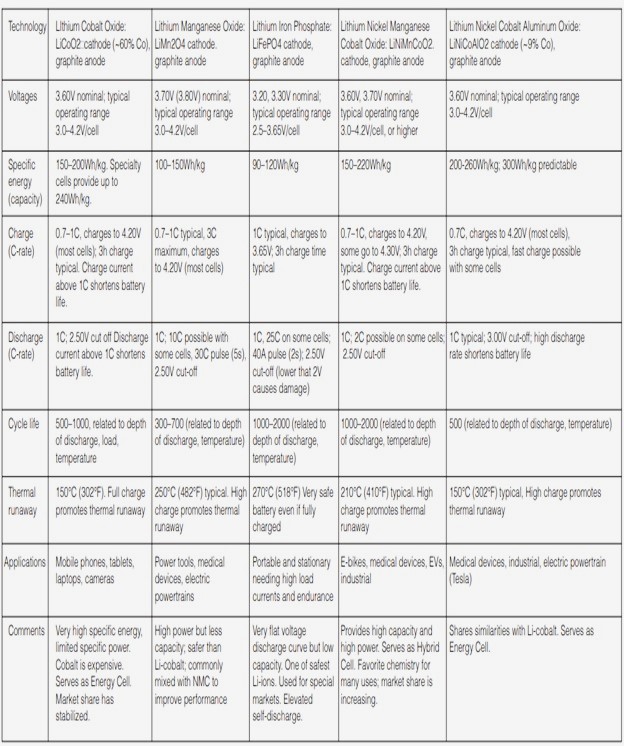

Different

Technologies of Lithium Ion Battery (see Fig.6) Fig-6 Different Technologies of Lithium Ion

Battery |

||||||

|

Batteries can be classified either

as:

The deep cycle means that the

battery is fully discharged and then recharged. From the outside, both

batteries look alike; however, there are fundamental differences in design as

per the following comparison table:

|

In the next Article, we will continue

explaining other Components of Online Double Conversion UPS. So, please keep following.

|

Subject Of Pervious

Article |

Article |

|

Applicable Standards for UPS Systems What is a UPS? Why do we need a UPS? UPS Rating Classification of UPS: 1-Voltage range, 2-No. of phases, 3- Mobility, 4- Technological design, |

Classification and Types of

UPS – Part One |

|

5- Physical Size/capacity, 6- Form factor/ configurations: 6.1- “N” System Configuration |

Classification and Types of UPS – Part Two |

|

6.2- “N+1” System

Configuration, which includes:

6.3- Parallel Redundant

with Dual Bus Configuration (N+1 or 1+1) |

Classification and Types of

UPS – Part Three |

|

6.4- Parallel Redundant with STS Configuration

6.5- System plus System

2(N+1), 2N+2, [(N+1) + (N+1)], and 2N |

Classification and Types of UPS – Part Four |

|

7- According to UPS Topology 7.1 Off-line or Standby UPS, 7.2 Line Interactive UPS, 7.3 Standby-Ferro UPS, 7.4 Online Double Conversion UPS, 7.5 The Delta Conversion On-Line UPS. |

Classification and Types of

UPS – Part Five |

|

8- According to UPS Distribution

Architecture 8.1 Centralized UPS Configuration, 8.2 Distributed (Decentralized) UPS Configuration, 8.2.1 Distributed UPS-Zonewise Configuration 8.3 Hybrid UPS Configuration. Conventional (Monolithic) Vs Modular

UPS System:

|

Classification and Types of UPS – Part Six |

|

Three Basic Configurations Of Mains And Bypass For A UPS System:

9-According to Use of transformers with the UPS

|

Classification and Types of

UPS – Part Seven |

|

Transformer Arrangements in Practical UPS Systems: 1-Transformer options for the “single mains” configuration 2-Transformer Options for the “Dual Mains” Configuration |

Classification and Types of UPS – Part Eight |

|

3-

Transformer options for “single mains without bypass” |

Classification and Types of

UPS – Part Nine |

No comments:

Post a Comment