Today, we will start explaining the

UPS design and sizing calculations, and as we do usually, we will start by

explaining the components and main types of UPS systems.

|

First:

Applicable Standards for UPS Systems

|

Throughout Our explanation of the UPS

systems, we will use the following standards:

1- Standards

Relevant to UPS Installations:

|

Standard

|

Details

|

|

CE

|

Marking in compliance with the

following European directives:

• Low Voltage Directive 2006/95/EC

• EMC Directive 2004/108/EC

|

|

ISO/IEC 27001:2005

|

Information Security Standards

|

|

BS 25999-1:2006

|

Business continuity management. Part

1: Code of practice

|

|

BS 7698-1:1993, ISO 8528-1:1993

|

Reciprocating internal combustion engine

driven alternating current generating sets. Specification for application,

ratings and performance

|

|

ER G59/1

|

Recommendations for the connection

of embedded generating plant to the Public Electricity Suppliers distribution

systems. Energy Networks Association

|

|

BS EN 60529:1992

|

Specification for degrees of protection

provided by enclosures (IP code) BS EN 60439-4:2004: Low-voltage switchgear

and control gear assemblies

|

|

BS 7671:2001

|

Requirements for electrical

installations. IEE Wiring Regulations. Sixteenth edition

|

|

BS EN 50310:2006

|

Application of equipotential bonding and

earthing in buildings with information technology equipment

|

|

BS EN 60439-4:2004

|

Low-voltage switchgear and control

gear assemblies

|

|

EN 60950:2006

|

Safety of information technology equipment

including electrical business equipments

|

2- Standards

Relevant to Lead Acid Batteries:

|

Standard

|

Details

|

|

BS 6133:1995

|

Code of practice for safe operation

of leadacid stationary batteries

|

|

BS 6290-4: 1997

|

Lead-acid stationary cells and batteries.

Specification for classifying valve regulated types

|

|

BS EN 60896-1:1992, IEC

|

Stationary lead-acid batteries.

General requirements and methods of test. Vented type

|

|

BS EN 60896-2:1996, IEC

|

Stationary lead-acid batteries. General

requirements and methods of test. Valve regulated type

|

|

BS EN 50272-2:2001

|

Safety requirements for secondary

batteries and battery installations. Stationary batteries

|

|

ANSI/IEEE 450-2002

|

IEEE recommended practice for maintenance,

testing and replacement of vented lead-acid batteries for stationary

applications

|

|

ANSI/IEEE 1184-1994

|

IEEE recommended guide for selection

and sizing batteries for Uninterruptible Power Supplies (UPS)

|

|

ANSI/IEEE 1188-1996

|

IEEE recommended practice for maintenance,

testing and replacement of valve-regulated lead-acid (VRLA) batteries for

stationary applications

|

|

What

is a UPS?

A

UPS is a combination of convertors, switches and energy storage devices (for

example, batteries), Constituting an alternate or backup source of power for

maintaining continuity of critical loads power in case of input power

failure.

|

|

Why do we need a UPS?

The

two main functions of the UPS are:

- Ensuring

continuity of an alternate power source,

- Improving

the quality of the power source by keeping it within specified

characteristics.

|

|

1-

Ensuring continuity of an alternate power source:

An

UPS can be considered as a source of standby power or emergency power

depending on the nature of the critical loads.

Typical

critical loads are:

- Computers

– e.g. data processing and control systems

- Industrial

process equipment – e.g. precision manufacturing

- Medical

equipment – e.g. life support and monitoring systems

- Telecommunications

network equipment – e.g. PABX

- Point

of sales (POS) terminals – e.g. retailing environment

- Online

business transactions – e.g. internet shopping.

- Emergency

lighting for evacuation,

- Emergency

perimeter lighting for security.

|

|

2-

Improving the quality of the power source by keeping it within specified

characteristics.

- Any

power system may face a variety of issues either from generation,

Transmission & Distribution (T&D) or even within a customer facility

which cause disturbance in the quality of power.

- The

Power quality disturbance can be defined as the deviation of the voltage and

the current from its ideal sinusoidal waveform.

- The

Power quality disturbance can affect the uninterrupted operation of customer

loads, reduce the life of the connected loads and electrical equipment and

affect other loads within the facility or even outside the customer facility.

The

Power Quality Issues and Causes are summarized in the following table:

|

|

Therefore,

The UPS can provides the following functions:

- Protection

of load against Line frequency variations,

- Elimination

of power line noise and voltage transients,

- Protection

of load against Voltage regulation.

- Safe

operation of equipment during sags and brownouts.

In

addition, some UPS or UPS/software combinations provide the following

functions:

- Automatic

shutdown of equipment during long power outages.

- Monitoring

and logging of the status of the power supply.

- Display the Voltage/Current draw of

the equipment.

|

|

UPS

Rating

- UPS

manufacturers generally use VA (or kVA) to describe the UPS output ratings;

this rating determines the maximum load that can continuously be supported by

the UPS when the mains supply fails.

- When

selecting a UPS to service a particular load it is important that the

combined load does not exceed the UPS output rating, and if the load

equipment is specified in Watts it is necessary to convert this to VA in

order to assess the UPS/load rating compatibility.

|

|

UPSs can be classified into many

types according to the following:

- Voltage range,

- No. of phases,

- Mobility,

- Technological design,

- Physical Size/capacity,

- Form factor/ configurations,

- Topology,

- Distribution Architecture,

- Use of transformers.

|

|

First:

According to Voltage Range

|

|

The IEC 60038 standard rates voltage

ranges as; low 0-1000v, medium 1000v - 35kv, and high as anything over 35kv.

Therefore, according to voltage

range, the UPS has two types:

- Low Voltage UPS,

- Medium voltage UPS.

|

|

1-

Low Voltage UPS

- At low voltage system levels of 400

volts or 480 volts a maximum capacity of approximately 5 MVA at the common

bus is reached very soon.

- The limitation to 5 MVA is given by

the current capability of bus bars and breakers of about 6000 amps on one

side and the short circuit capability of the switchboards of typically 100 kA

on the other side.

- Higher ratings of both will let the

costs and the dimensions of the switchgear increase dramatically while the

component availability in the market is very limited. Additionally, high

currents require high copper cross sections and cause rather high resistive

losses, both resulting in increasing costs for power transmission. A way to

reduce the currents and to enable a further increase of the power is the move

to a medium voltage (MV) system level.

|

|

2-

Medium voltage UPS

- A medium-voltage UPS is essentially

the same as a standard UPS but is designed for a medium-voltage range,

ranging from 1000v - 35kV. The major difference between a low voltage (LV)

UPS and a medium voltage (MV) UPS is the source voltage. Both systems will store

power in the event of a power outage. Both systems filter the incoming

voltage to provide clean source voltage to the downstream devices. A typical

MV UPS is used for data centers or any mission-critical facility requiring

clean, constant electrical power.

- For example, at a typical MV level

of 13.2 kV, the maximum system power rises up to 27 MVA using a standard MV

breaker size of 1200 amps and up to 57 MVA with a breaker size of 2500 amps.

Medium voltage levels go up as high as 34.5 kV, allowing a system power

rating of up to 70 MVA.

- The

transition from low voltage (LV) to medium voltage (MV) level is a natural

progression of power protection for large critical power facilities. The

approach offers three main benefits as follows:

- Increased

reliability because the MV design approach comes with larger protected load

blocks, lower switchgear count and the operating culture of medium voltage

systems.

- Reducing

the costs because installing the power protection at the MV level provides

the most energy efficient configuration as the lower currents at this voltage

result in smaller cables and lower losses.

- Reducing the floor space for

infrastructure equipment like power supplies results in additional space for

IT or manufacturing equipment. Often the available area for the UPS system is

given and limited, particularly in existing buildings, but the required power

is increasing.

|

|

Second:

According to No. of phases

|

|

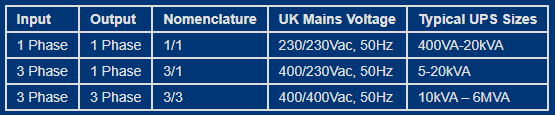

The input/output phase configurations of UPS

systems are available in:

- Single-phase configuration (1/1) or

- Three-phase configuration (3/3 and

3/1).

The

common phase configurations for UPS are:

|

|

1- Single Phase UPS System (1/1)

- A

single phase installation consists of two wires where AC voltage is a single

sine wave. The standard voltage of single phase varies in different countries

or regions. The standard single phase voltage in America is 120V and Europe,

Asia or other regions take 230V as a standard voltage.

- Single-phase uninterruptible

power supplies typically cover requirements up to 20 kVA and

are used for smaller installations such as rack-mounted servers, telecoms or

computer systems, and network switches, along with any device that runs

directly from a standard three-pin plug.

- A 20kVA output is generally the largest single phase UPS system

available. This is due to the output amperage and cable requirements.

20kVA=20,000VA / 230Vac = 86.9Amps.

|

|

2- Three Phase UPS System (3/3 and 3/1)

The

three phase UPS can be subdivided into:

- Three

phase input/three phase output UPS system (3/3),

- Three

phase input/single phase output system (3/1).

- If

you need to connect to a three phase supply, you must need a UPS with a 3/x

configuration. A 3/1 UPS takes in 3 phase power but delivers single phase to

the downstream load while a 3/3 UPS not only takes in but also puts out 3

phase power.

- Three-phase

UPS are the standard choice for larger

installations with critical loads such as data centers, industrial

applications, and medical environments,

as well as protecting equipment with motors such as lifts, pumps,

and fans.

- With a three-phase system,

consideration should be given to phase load balancing and load power factors

to minimize the imbalance in the output voltage.

|

Three-phase power

|

Single-phase power

|

|

common in

most large businesses and high-density data centers with higher kVA and

rack applications.

|

Used in most

residential homes and small businesses.

Used for a

wide range of general applications.

|

|

Used for

applications requiring greater than 1000 watts.

|

Is the most efficient for units up

to 1000 watts.

|

|

Used to

balance the loads on the utility power of the building.

Is safer and

more cost effective to run.

|

The standard

for locations where three-phase power is unavailable.

|

|

Delivered in

a steady stream at a constant rate.

|

Not delivered at a constant rate.

|

|

|

Third: According to Mobility

|

|

UPS

can be classified according to Mobility to:

- Movable,

- Stationary,

- Fixed,

- Building-in.

|

|

1-

Movable UPS (transportable):

An

UPS that is either 18 kg or less in mass and not fixed comes usually with

wheels, castors or other means to facilitate movement by the operator as

required to perform its intended use in different locations.

2-

Stationary UPS:

An

UPS that that exceeds 18kg and is not provided with a carry handle or wheels.

3-

Fixed UPS:

An

UPS that is fastened to a support or otherwise secured in a specific

location, e.g. open Rack or Stand.

4-

UPS for “building in”:

An

UPS intended to be installed in a prepared recess such as a cupboards, closed

racks etc.

|

|

Fourth: According to Technological Design

|

|

The design technologies of ups

systems are different and can be classified into two main types:

- Static UPS,

- Rotary UPS.

|

|

1-

Static UPS

- The static UPS is called

“static” because, throughout its power path, it has no moving parts (although

it has auxiliary moving parts, such as cooling fans).

- The rectifier inside of

the static UPS converts the incoming utility AC current to DC, and the

inverter converts DC back to clean sine-wave AC to supply the load.

- The DC current

interfaces with the “energy storage” medium – most commonly batteries, in

which case it charges the batteries and receives power from the batteries

when the utility power supply is distorted or fails.

|

|

2-

Rotary UPS

- The rotary UPS is called “rotary” because rotating

components (such as a motor-generator) within the UPS are used to transfer

power to the load.

- Rotary technology has been utilized for many years especially

in the following conditions:

- When loads would commonly exhibit a low power factor

(which resulted in increased losses in the power distribution system and

thus, an increased energy cost),

- When loads would commonly exhibit high harmonics

(which prematurely shortened the life of transformers and capacitors),

- When loads would commonly exhibit high voltage dips

and sags for example when large motors turned on, Users would experience the

dimming of lights

Thus, the introduction of the rotary UPS to address this issues.

|

|

2.1 Types of Rotary UPS

The rotary UPS has two main types as

follows:

- Motor-generator / battery rotary UPS,

- Engine-coupled rotary UPS.

|

|

2.1.1 Motor-Generator / Battery

Rotary UPS

- When the utility power quality (voltage and frequency) falls

within an acceptable range, then the motor component of the rotary UPS is

driven directly from the utility. That motor then provides mechanical power

to the generator component of the motor-generator to support the critical

load with clean power. Also, the rectifier / inverter unit operates in

stand-by mode during the time the utility is stable. That is, the rectifier

is in “battery float” mode (the batteries get charged).

- When utility voltage and frequency parameters fall outside of

preset limits, then the rectifier / inverter unit begins to provide

controlled power to the motor which is coupled directly to the generator to

support the critical load. When a blackout occurs, the battery bank provides

necessary power via the inverter to the motor-generator to support the load.

The stored energy within the batteries provides sufficient ride-through to

sustain the load until the standby generator (outside of the UPS) comes up to

full operating speed.

|

|

2.1.2 Engine-Coupled Rotary UPS

- The key components of an engine-coupled rotary UPS include the

following: a motor-generator, a choke, a flywheel, a mechanical clutch, and a

diesel engine.

- Under normal operation, the utility feeds power to the critical

load via the filter (made up of the choke and motor). The same motor also

provides the necessary power to the flywheel to retain kinetic storage of

energy in case of emergency.

- During

failure mode, power is supplied by the flywheel to the motor-generator unit,

which in turn supports the critical load for a few seconds before the diesel

engine runs up to full speed. The clutch is then engaged to provide

mechanical power to the motor-generator to supply continuity of power to the

load.

|

|

2.2 Comparison Of Static and Rotary

UPS Architectures

The range of applications for static

UPSs is broad while the application ranges of rotary UPSs are more limited.

In the domain of the data center, static UPSs represent the technology of

choice. Rotary UPSs become more competitive in very large multiple megawatt

data centers.

|

In the next Article, I will continue explaining other

classifications of UPS. So,

please keep following.

.png)

.jpg)

.png)

.png)

.png)

.png)

.png)

Thanks Eng. Hassan For All your Effort. Very Interesting Information. Hope you More Successful

ReplyDeleteQuite satisfactory. Well done.

ReplyDeleteI have learned some useful specifications details to consider when am planning on buying a UPS device. Thanks for sharing.

ReplyDeleteVery Useful technical Artical, Thanks Eng. Hassan.

ReplyDeleteThanks, Ing Hassan

ReplyDelete