In Article " Introduction to Lightning System Design- Part One ", I listed all terms, abbreviations and Symbols used in lightning field.

Also, in Article " Introduction to Lightning System Design- Part Two ", I answered the following questions:

Also, in Article " Introduction to Lightning System Design- Part Two ", I answered the following questions:

- What is Lightning?

- What are the types of Lightning flashes?

- What is the shape of The Lightning Waveform?

- How Lightning strikes can affect the electrical and/or electronic systems of a building?

- What are the main effects of Lightning?

And in Article " Types Of Lightning Protection Systems LPS ", I list the main types of Lightning Protection Systems as follows:

Types of Lightning Protection Systems LPS

|

Types of Lightning Protection Systems LPS

Lightning protection systems for buildings and installations may be divided into three principal types as follows:

1- LPS for Protection for buildings and installations against direct strike by lightning, which includes:

A- Conventional lightning protection system, which includes:

B- Non-Conventional lightning protection system, which includes:

a- Active Attraction LPS, which includes:

b- Active Prevention/Elimination LPS, which includes:

2- LPS for Protection against overvoltage on incoming conductors and conductor systems,

3- LPS for Protection against the electromagnetic pulse of the lightning.

Notes on different Types of Lightning Protection Systems LPS

Each system’s design requires the following:

|

And in Article " Conventional Lightning Protection System Components – Part One ", I indicated the Conventional Lightning Protection System parts and components as follows:

Conventional Lightning Protection System LPS Components

The Conventional Lightning Protection System consists of

two main parts:

1- The External Lightning Protection System, which includes:

2- The Internal Lightning Protection System, which includes:

Another important components of the

Lightning Protection System is the Connection Components which

include but not limited to:

|

And I explained the Strike Termination Subsystem in this Article.

Also, in Article " Conventional Lightning Protection System Components – Part Two ", I began explaining the Conductor Subsystem through the following points:

- Function of Conductor Subsystems,

- Effects of Lightning Strikes on Conductor Subsystems,

- Conductor Subsystem Material Requirements.

Today, I will continue explaining the Conductor Subsystem through the following points:

- Types of Lightning Conductors,

- Installation Requirements For Down Conductors.

Conductor Subsystem -Continued

|

2- Types of the Conductors in

Conductor Subsystems

The Conductor Subsystem is consisting of two types of conductors as

follows:

Note:

It is possible that the same conductor type may be used for:

|

2.1 The

Air-Termination Conductors (The Main

Conductors)

The Air-Termination Conductors is the electrically conductive

connection between the air-termination system and the down conductors.

|

2.2 Down Conductors (The Extension Conductors)

|

2.2.A Down-Conductors for a Non-Isolated

Lightning Protection System

In non-isolated

lightning protection system, the down-conductors are primarily mounted

directly onto the structure (with no distance).

But, sometimes

a separation distance is required between the down conductors and the

structure. This is governed by the criteria of temperature rise in the event

of lightning striking the lightning protection system.

Temperature

Rise Criteria:

The

temperature rise criterion is based on the level of flammability for the

structure walls; we have two cases as follows:

Case#1: If

the wall is made of flame-resistant material or material with a normal level

of flammability

In this

case, the down-conductor systems may be installed directly on or in the wall.

For example,

Wood with a bulk density greater than 400 kg/m2 and a thickness greater than

2 mm is considered to have a normal level of flammability. Hence the

down-conductor system can be mounted on wooden poles.

Case#2: If

the wall is made of highly flammable material

In this

case, we have two sub-cases according to considering the temperature rise

(when lightning currents flow) is a hazard or not, this is can be known from

table as follows:

the below Table states

the maximum temperature rise ΔT in K of the various conductors for each class

of lightning protection system. These values mean that, generally, it is even

permissible to install down conductors underneath heat insulation because

these temperature rises present no fire risk to the insulation materials.

This ensures that the fire retardation measure is also provided.

So, the two

sub-cases for case#2: If the wall is made of highly flammable material, are:

Case#2-A:

The temperature rise of the down-conductor systems is not hazardous

In this

case, the down conductors can be installed directly on the surface of the

wall.

Case#2-B: The temperature rise of the down-conductor

systems presents a hazard

In this

case, the down conductors must be mounted (by using Standoff brackets for

example)(see fig.1) to ensure that the separation distance between the down-conductor

and the wall is greater than 0.1 m. The mounting elements may touch the wall.

Notes:

|

2.2.A.1 Requirements of Down

Conductor Installation In Non-Isolated Lighting Protection System

The following

requirements for Down Conductor Installation in Non-Isolated

Lighting Protection System must be considered:

|

2.2.B Down conductors of an isolated external

lightning protection system

The

general requirements for down-conductors in an isolated LPS are:

|

3- Installation Requirements For Down

Conductors

|

3.1 General Consideration

For Down Conductors Installation

To avoid

damage caused during the lightning current discharge to the earth-termination

system such as side flash which depends on inductance value of the down

conductors. The following requirements must be considered:

|

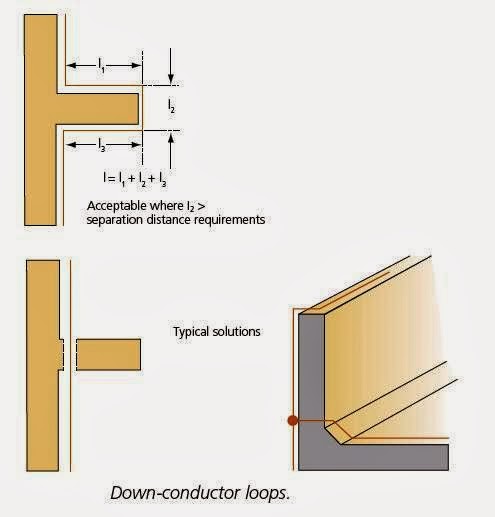

3.2 Down Conductor Routing

The criterion for the

best routing of down conductors is as follows:

We have many cases

where special solutions must be provided for correct routing of down

conductors as follows:

1- Structures with

overhangs

h>2.5+ s

Where:

h = Height of the

overhang (in meters),

s = Required

separation distance calculated in accordance with Section 6.3 of BS EN

62305-3.

2-

Routing Down Conductors within Walls, Or the Wall Cavity

Care is

required in routing conductors within walls, or the wall cavity:

3- Large

Flat Structures

4-

Courtyards

Structures

with enclosed courtyards having a perimeter greater than 30 m (see fig) must have down-conductor

systems installed with the distances (see fig.11).

|

3.3 Fixing Of Down Conductors

Fixing

centers for the air termination and down conductors are shown in below Table:

|

3.4 Measuring Points (Test Joints)

Each down conductor will be

provided with a test joint designed and situated to:

Notes:

|

In the next Article, I will explain How to use Natural Structure Components as down Conductors. Please, keep following.

No comments:

Post a Comment