In Article " Introduction to Lightning System Design- Part One ", I listed all terms, abbreviations and Symbols used in lightning field.

Also, in Article " Introduction to Lightning System Design- Part Two ", I answered the following questions:

- What is Lightning?

- What are the types of Lightning flashes?

- What is the shape of The Lightning Waveform?

- How Lightning strikes can affect the electrical and/or electronic systems of a building?

- What are the main effects of Lightning?

And in Article " Types Of Lightning Protection Systems LPS ", I list the main types of Lightning Protection Systems as follows:

Types of Lightning Protection Systems LPS

|

Types of Lightning Protection Systems LPS

Lightning protection

systems for buildings and installations may be divided into three principal

types as follows:

|

1- LPS for Protection for buildings and installations

against direct strike by lightning

This type of LPS protects

the building from damage by direct strike lightning but doesn’t prevent the

lightning striking the building. This type of LPS can be divided into:-

|

1.1 Types of Conventional Lightning Protection

System

The Conventional Lightning Protection System includes (2)

different types as follows:

|

1.2 Types of Non-Conventional Lightning Protection

System

The Conventional Lightning Protection System includes

(2) different types as follows:

1- Active Attraction

LPS, which includes:

2- Active Prevention/Elimination

LPS, which includes:

|

Notes on different Types

of Lightning Protection Systems LPS

Each system’s design

requires the following:

|

Today, I will explain the Conventional Lightning Protection System LPS Components.

Conventional Lightning Protection System LPS Components

|

Conventional Lightning Protection System LPS Components

The Conventional Lightning Protection System consists of (2) main parts (see Fig.1) :

1- The External Lightning Protection System, which includes:

2- The Internal Lightning Protection System, which includes:

Another important components of the Lightning Protection System is the Connection Components which include but not limited to:

|

1- The External Lightning

Protection System

|

Functions of External Lightning Protection System

The functions of the

external lightning protection are:

|

Components of External

Lightning Protection System

External Lightning

protection systems have (3) distinct subsystems (see Fig.1), They are:

These

individual Subsystems of an external LPS should be connected together using

appropriate lightning protection components (LPC). This will ensure that in

the event of a lightning current discharge to the structure, the correct

design and choice of components will minimize any potential damage.

|

1- Strike Termination Subsystem

Usually called "Air Termination

Subsystem", the purpose of the strike termination subsystem is to intercept

the lightning event and course it harmlessly into the conductor subsystem. Thus it is

vitally important to use a correctly designed air termination system.

When

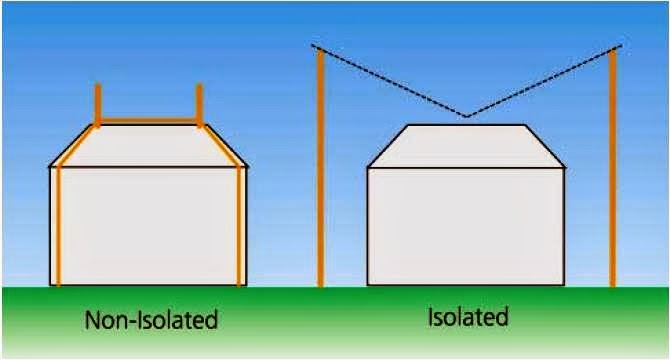

designing the external lightning protection system of a structure, we

distinguish between two types of air-termination system (see Fig.2):

1- Non-Isolated

System:

2- Isolated System:

|

Forms of Strike Termination Subsystem

The strike

termination subsystem can take many forms specified by the various engineering standards available (see Fig.3), as follows:

1- Vertical Air Terminals:

2- Horizontal air termination network:

The

horizontal air termination networks have (2) method of installation:

A- Meshed conductor network:

- Meshed

conductor network is installed by (2) ways:

- Meshed

conductor network usually uses bare copper strip (25×3 mm for example) which

will be supported at equal intervals.

- Meshed conductor network can be applied in two

sizes:

(5 m X 10 m) mesh,

(10 m X 20 m) mesh.

The first one is used in

high risk structure such as

explosives factors.

B- Overhead wires (Catenary wires):

One or more

catenary conductors may be utilized to provide a zone of protection over an

entire structure. Catenary (or suspended) conductors, whether they are

supported by free standing masts or linked with conductors to form a mesh on

the roof.

3- Combination of Vertical

Air Terminals and Horizontal air termination network

that is used in important buildings for increasing the protection against Lightning strikes, where Vertical Air Terminals and Horizontal air termination can combined together to consist one Air Termination System.

4- Natural Air Terminals:

Notes:

|

In the next Article, I will continue explaining the Conventional Lightning Protection System LPS Components. Please, keep following.

No comments:

Post a Comment