In article " Voltage drop calculations- Part One ", I indicated that there are eight methods for Voltage Drop Calculations as follows:

1- Ohm’s Law Method,

2- European method,

3- U.S method which divided to:

- Circular-mils method,

- Chapter (9) tables method.

5- Quick On-Line method,

6- Ampere-Feet method,

7- Lookup tables,

8- Excel spreadsheets.

And I explained the first two methods: Ohm’s Law Method and European Methods in this Article.

And, I explained the third method: U.S Method- Circular-mils Method In Article " Voltage drop calculations- Part Two ",

And, I explained the third method: U.S Method- Chapter (9) tables Method In Articles:

And, in Article " Voltage Drop Calculations- Part Four ", I explained the following methods for Voltage Drop Calculations:

- Approximate Mathematical method,

- Ampere-Feet method,

- Lookup tables,

Also, in Article " Voltage Drop Calculations- Part Five ", I explained the Quick On-Line Method with (8) Voltage Drop Calculators.

Today I will continue explaining other methods for Voltage Drop Calculations as follows.

8- Excel Spreadsheets Method for Voltage Drop Calculations

8- Excel Spreadsheets Method for Voltage Drop Calculations

Under this method, I will explain the following excel

spreadsheets for Voltage Drop Calculations:

First: Excel Spreadsheet for US / NEC Methods:

Second: Excel Spreadsheet for European Method /Code

|

First: Excel Spreadsheet for US / NEC Methods:

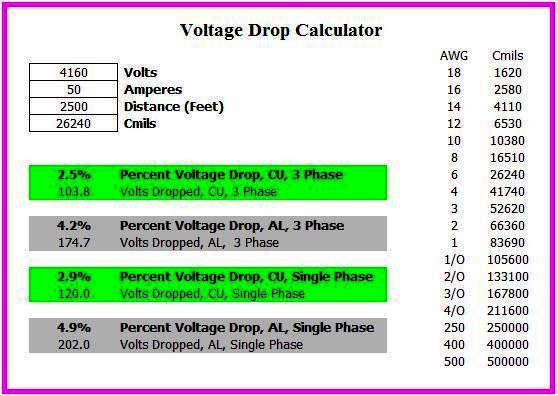

1- Excel

Spreadsheet for Voltage Drop Calculator

This Excel Spreadsheet Calculate

the Voltage Drop as per US- Circular Mils Method.

How to use this Excel Spreadsheet:

1- Put the input data which are:

Note: if you have the Cable Cross section

Area in AWG/Kcmil use the shown table to get the equivalent Cmils.

2- Get Voltage drop (V D) in V from the

following Formula:

3- Get Voltage drop (V D) in percent from the

following Formula:

(V

D) % = Voltage drop (V D) in V x 100 / Voltage

4- From the Results section, select the Result that match with the

actual method of installation from the following choices:

5- If the (V D %) > the predetermined

Value according to Country Regulations (2.5 % or 3%), change the Cable Cross

section Area in Cmils with a higher size.

|

2- Excel Spreadsheet for Voltage Drop

Calculations

This Excel Spreadsheet Calculate

the following as per US- Chapter (9) Tables Method:

How to use this Excel Spreadsheet:

1- Fill in blank

cells 1 to 8 as follows:

Note: if the

wire is smaller than 1/0 AWG, then Parallel wires are not allowed except per

310.4 exceptions.

2- The Result

Window will show the following Calculated

information (in grey color) which are:

Notes:

|

3- Siemens Voltage Drop Calculations Spreadsheet

This voltage drop calculator will provide an approximate

value for use in project design. You can review this spreadsheet in the Previous

Article "Siemens Voltage Drop Calculations Spreadsheet ".

|

Second:

Excel Spreadsheet for European

Method /Code

2- Excel

Spreadsheet for 3-Phase Voltage Drop Calculations

This Excel Spreadsheet Calculate

only the 3-Phase

Voltage Drop as per

European method /Code.

How to use this Excel Spreadsheet:

1- Put the required general data which are:

2- Put the Load data which are:

Load Current (A) = (Load power (KW) x 1000) / (√3 x Voltage (V) x P.F)

Note: If P.F is unknown, you can use P.F = 0.85

3- Put the Cable Data which are:

4- Get Voltage drop (V D) in Volts from the following Formula:

Voltage drop (V D) = K x Load Current (A) x Length (L) / 1000

5- Get Voltage drop (V D) in Percent from the following Formula:

(V D %) = (V D x 100 / Voltage)

6- if the (V D %) > the predetermined Value according to Country

Regulations (2.5 % or 3%), you must re-select another cable with higher size

and repeat the calculations.

Notes:

|

End of Course EE-4 |

جزاك الله خيرا

ReplyDelete