In the previous topic ” Classification of Electric Motors -

Part Four “, I explained the Synchronous motor construction and applications. Also, I explained the first type of Synchronous motor which was the Non-excited motors.

Today, I will explain the second type of Synchronous motor which is DC-excited motors in addition to the Linear motors as follows.

You can review the following related topics for review and good following.

- Electrical Motors Basic Components

- Classification of Electric Motors – Part One

- Classification of Electric Motors - Part Two

- Classification of Electric Motors - Part Three

2- DC-excited motors

They are made in sizes larger than 1 hp, these motors require direct current for excitation which can be supplied from a separate source or from a dc generator directly connected to the motor shaft.

These motors are commonly used in analog electric clocks, timers and other devices where correct time is required.

Two common approaches are used to supply a DC current to the field circuits on the rotating rotor:

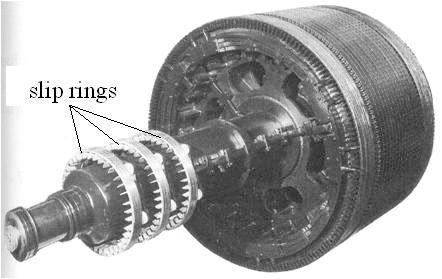

- Supply the DC power from an external DC source to the rotor by means of slip rings and brushes “Brush type Synchronous motors”.

- Supply the DC power from a special DC power source mounted directly on the shaft of the machine “brushless type Synchronous motors”.

A- Brush type Synchronous motors:

|

| Brush type Synchronous motors |

The field exciter for a brush-type motor is typically a DC generator with its rotor mounted on the motor shaft. The output of the DC generator is fed via brushes and slip rings to the motor field windings.

A brush-style exciter is typically not used in a high speed application due to ignition problems caused by the brushes’ physical contact with the slip ring. Proper and regular maintenance, though difficult to perform, can reduce the occurrence of ignition problems in brush-type exciters

B- Brushless type Synchronous motors:

|

| A rotor of large synchronous machine with a brushless exciter mounted on the same shaft. |

|

| Solid-State Rectifier for Brushless Motor |

It is possible to adjust the field current on the main machine by controlling the small DC field current of the exciter generator (located on the stator).

Note: In either design; brush and brushless, the field excitation to the exciter may be varied to vary the power-factor operation of the motor, and in fact power factor correction is one common use of synchronous motors since they can be made to operate at leading power factors.

Note: In either design; brush and brushless, the field excitation to the exciter may be varied to vary the power-factor operation of the motor, and in fact power factor correction is one common use of synchronous motors since they can be made to operate at leading power factors.

3- Stepper motor:

Stepper motor is a special type of synchronous motor which is designed to rotate a specific number of degrees for every electric pulse received by its control unit. Typical steps are 7.5 or 15 degree per pulse.

It is a motor that can rotate in both directions, move in precise angular increments, sustain a holding torque at zero speed, and be controlled with digital circuits. It moves in accurate angular increments known as steps, in response to the application of digital pulses to the electric drive circuit.

Generally, such motors are manufactured with steps per revolution. Depending on its electrical power supply, it may be:

A- Unipolar: if its coils are always supplied in the same direction by a single voltage, it requiring only one power source, hence the name unipolar.

B- Bipolar: when its coils are supplied sometimes in one direction and sometimes in the other, it requiring two power sources. They sometimes create a North Pole, and sometimes a South pole, hence the name bipolar.

Stepper motors, unlike ordinary DC motors, are brushless and can divide a full 360° into a large number of steps, for example 200.

Operating principles:

Stepper motors operate differently from normal DC motors, which rotate when voltage is applied to their terminals. Stepper motors, on the other hand, effectively have multiple "toothed" electromagnets arranged around a central gear-shaped piece of iron. The electromagnets are energized by an external control circuit, such as a micro controller.

To make the motor shaft turn, first one electromagnet is given power, which makes the gear's teeth magnetically attracted to the electromagnet's teeth. When the gear's teeth are thus aligned to the first electromagnet, they are slightly offset from the next electromagnet. So when the next electromagnet is turned on and the first is turned off, the gear rotates slightly to align with the next one, and from there the process is repeated. Each of those slight rotations is called a "step," with an integer number of steps making a full rotation. In that way, the motor can be turned by a precise angle.

Advantages:

Disadvantages:

To make the motor shaft turn, first one electromagnet is given power, which makes the gear's teeth magnetically attracted to the electromagnet's teeth. When the gear's teeth are thus aligned to the first electromagnet, they are slightly offset from the next electromagnet. So when the next electromagnet is turned on and the first is turned off, the gear rotates slightly to align with the next one, and from there the process is repeated. Each of those slight rotations is called a "step," with an integer number of steps making a full rotation. In that way, the motor can be turned by a precise angle.

Advantages:

- Low cost.

- Can work in an open loop (no feedback required).

- Excellent holding torque (eliminated brakes/clutches).

- Excellent torque at low speeds.

- Low maintenance (brushless).

- Very rugged - any environment.

- Excellent for precise positioning control.

- No tuning required.

Disadvantages:

Some of the disadvantages of stepper motors in comparison with servo motors are as follows:

- Rough performance at low speeds unless you use micro-stepping.

- Consume current regardless of load.

- Limited sizes available.

- Noisy.

- Torque decreases with speed (you need an oversized motor for higher torque at higher speeds).

- Stepper motors can stall or lose position running without a control loop.

Applications of Stepper motor:

- Cruise control.

- Auto air vents.

- Light leveling.

- Printers.

- Industrial machines.

- Automotive gauges.

- Office equipment.

- Computer drives.

- Medical scanners.

- Scientific Instrumentation.

Types of Stepper Motors:

1- Variable-Reluctance Step Motors

|

| Variable-Reluctance Step Motors |

The construction of variable-reluctance (VR) motors is generally as shown in above image, there is a stator assembly consisting of an insulated lamination stack with copper coils wound around the teeth. The stator assembly is positioned within a housing or main frame such that its location is secured. The rotor assembly consists of a steel magnetic core, a steel output shaft, and bearings. The rotor assembly is centrally located inside the stator assembly by end frames or bearing supports.

2- Permanent-Magnet-Rotor Step Motors

|

| Permanent-Magnet-Rotor Step Motors |

The PM step motor is illustrated in above image. It consists of two sets of stamped steel cups with diagonal teeth facing the rotor. Each set of cups circumscribes a coil of wire. The two sets are positioned with respect to each other such that they circumscribe the rotor but they are offset from each other by one-half of a tooth pitch.

The permanent-magnet-rotor step motor is commonly referred to as the stamped-construction or sheet-metal step motor. It is sometimes called simply a PM step motor but should not be confused with the hybrid permanent-magnet step motor.

The rotor in a stamped-construction motor is a smooth cylindrical permanent magnet radially magnetized with alternating N and S poles.

The stator has two cup-shaped halves with formed stator teeth. Each half contains a circular, bobbin-wound coil. Because of this simple design, the price is low, but step accuracy and speed may not equal the performance of other step-motor types.

3- Hybrid Permanent-Magnet Step Motors

|

| Hybrid Permanent-Magnet Step Motors |

The hybrid step motor is generally constructed as shown in above image. It has a stator assembly similar to that of the VR motor, but the rotor consists of three sections.

Two pieces are similar to the VR step-motor rotor, but a magnet is placed between them, and they are offset circumferentially from each other by one-half tooth pitch.

This motor is termed a hybrid because it uses elements of both variable reluctance and permanent-magnet-rotor step motors. The commonly known version is the 1.8 step-angle motor. It was originally designed as an ac two-phase synchronous inductor motor for low-speed applications.

Its stator construction is similar to that of a variable-reluctance step motor with salient poles (multiple teeth per pole).The phase windings may be either monofilar or bifilar coils, as discussed for the stamped-construction motor. The rotor contains a cylindrical permanent magnet axially magnetized and enclosed on each end by a soft-iron cup with uniformly spaced teeth. As for the variable-reluctance motor, the number of stator phases and differing number of stator and rotor teeth determine the step angle.

Third: Linear motors

Linear motors should be thought of as rotary electric motors that have been cut along a radial plane and unrolled. The resultant motor is a linear electric motor that can produce linear motion without the need of pneumatic or hydraulic cylinders or translation of rotary motion with the use of belts, pulleys, or screws. This is desirable because the extra machine parts make the machine more complicated, and there are more parts that will wear out, and need replacement.

However, because linear motors do not have the luxury of 360 degree contained rotation, they must either increase the length of the primary, coil assembly, and keep a short moving secondary, magnet assembly, or increase the length of the secondary, and keep a short moving primary. There is a diagram that can be found below illustrating the differences between these two options.

So, a linear motor is an electric motor that has had its stator and rotor "unrolled" so that instead of producing a torque (rotation) it produces a linear force along its length. Linear electric motors can drive a linear motion load without intermediate gears, screws, or crank shafts.

Applications:

- Sliding doors and various similar actuators.

- Accelerating cars for crash tests.

- Transportation (Trains).

- Robotics & Material Handling.

- Elevators.

- Compressors & Pumps.

- Catapults and Launchers.

- Curtain pullers.

Types:

there are two main types of Linear Motors as follows:

- Linear induction motor (LIM).

- Linear synchronous motor (LSM).

1- Linear induction motor (LIM)

|

| Linear induction motor (LIM) |

A linear induction motor (LIM) is an AC asynchronous linear motor that works by the same general principles as other induction motors but is very typically designed to directly produce motion in a straight line. Characteristically, linear induction motors have a finite length primary, which generates end-effects, whereas with a conventional induction motor the primary is arranged in an endless loop.

Linear motors frequently run on a 3 phase power supply.

Despite their name, not all linear induction motors produce linear motion, some linear induction motors are employed for generating rotations of large diameters where the use of a continuous primary would be very expensive.

Construction:

Linear motors frequently run on a 3 phase power supply.

Despite their name, not all linear induction motors produce linear motion, some linear induction motors are employed for generating rotations of large diameters where the use of a continuous primary would be very expensive.

Construction:

|

| Traditional Linear Motors |

A linear electric motor's primary typically consists of a flat magnetic core (generally laminated) with transverse slots which are often straight cut with coils laid into the slots.

The secondary is frequently a sheet of aluminum, often with an iron backing plate. Some LIMs are double sided, with one primary either side of the secondary, and in this case no iron backing is needed.

Two sorts of linear motor exist, short primary, where the coils are truncated shorter than the secondary, and a short secondary where the conductive plate is smaller. Short secondary LIMs are often wound as parallel connections between coils of the same phase, whereas short primaries are usually wound in series.

The primaries of transverse flux LIMs have a series of twin poles lying transversely side-by-side, with opposite winding directions.

Principles of operation

a- Moving magnetic field

In this design of electric motor, the force is produced by a moving linear magnetic field acting on conductors in the field. Any conductor, be it a loop, a coil or simply a piece of plate metal, that is placed in this field will have eddy currents induced in it thus creating an opposing magnetic field, in accordance with Lenz's law. The two opposing fields will repel each other, thus creating motion as the magnetic field sweeps through the metal.

b- End effect

Unlike a circular induction motor, a linear induction motor shows end effects.

With a short secondary, the behavior is almost identical to a rotary machine, provided it is at least two poles long, but with a short primary reduction in thrust occurs at low slip (below about 0.3) until it is eight poles or longer.

However, because of end effect, linear motors cannot 'run light'- normal induction motors are able to run the motor with a near synchronous field under low load conditions. Due to end effect this creates much more significant losses with linear motors.

c- Levitation

In addition, unlike a rotary motor, an electrodynamics levitation force is shown, this is zero at zero slip, and tends to a constant positive lift force as slip increases in either direction.

2- Linear synchronous motor (LSM)

|

| Linear synchronous motor (LSM) |

A linear synchronous motor (LSM) is a linear motor in which the mechanical motion is in synchronism with the magnetic field, i.e., the mechanical speed is the same as the speed of the traveling magnetic field. The thrust (propulsion force) can be generated as an action of the following two fields:

- traveling magnetic field produced by a polyphase winding and an array of magnetic poles N, S,...,N, S or a variable reluctance ferromagnetic rail (LSMs with a.c. armature windings);

- Magnetic field produced by electronically switched d.c. windings and an array of magnetic poles N, S,...,N, S or variable reluctance ferromagnetic rail (linear stepping or switched reluctance motors).

The part producing the traveling magnetic field is called the armature or forcer. The part that provides the d.c. magnetic flux or variable reluctance is called the field excitation system (if the excitation system exists) or salientpole rail, reaction rail, or variable reluctance platen.

In the next Topic, I will explain Motor selection procedures . So, please keep following.

Note: these topics about Motors in this course EE-1: Beginner's electrical design course is an introduction only for beginners to know general basic information about Motors and Pumps as a type of Power loads. But in other levels of our electrical design courses, we will show and explain in detail the Motor and Pumps Loads calculations.